Relays are indispensable components in modern electronics manufacturing, offering precise control, protection, and automation across a wide range of industrial systems. From power distribution to PCB-level switching, relays serve as the backbone of many control and safety mechanisms. For electronics manufacturing professionals, understanding the types and applications of relays is essential for designing reliable and efficient systems.

The role of relays in industrial and manufacturing systems

Relays are electrically operated switches that allow low-power signals to control high-power circuits. In manufacturing environments, they are used to manage everything from motor starters and lighting systems to automated production lines and safety interlocks.

Control relays are commonly used in automation panels to manage logic operations and signal routing. These relays enable the coordination of multiple devices, ensuring that operations follow a defined sequence.

Industrial relays, designed for rugged environments, offer high durability and resistance to vibration, temperature, and electrical noise, making them ideal for factory floors and heavy machinery.

Power relays handle higher current loads and are often found in HVAC systems, industrial ovens, and large motors. Their ability to switch high voltages safely makes them critical in energy-intensive applications.

Relay types and their manufacturing use cases

|

PCB Relays

Compact and designed for direct mounting on printed circuit boards. Ideal for consumer electronics, instrumentation, and control systems where space is limited.

|

|

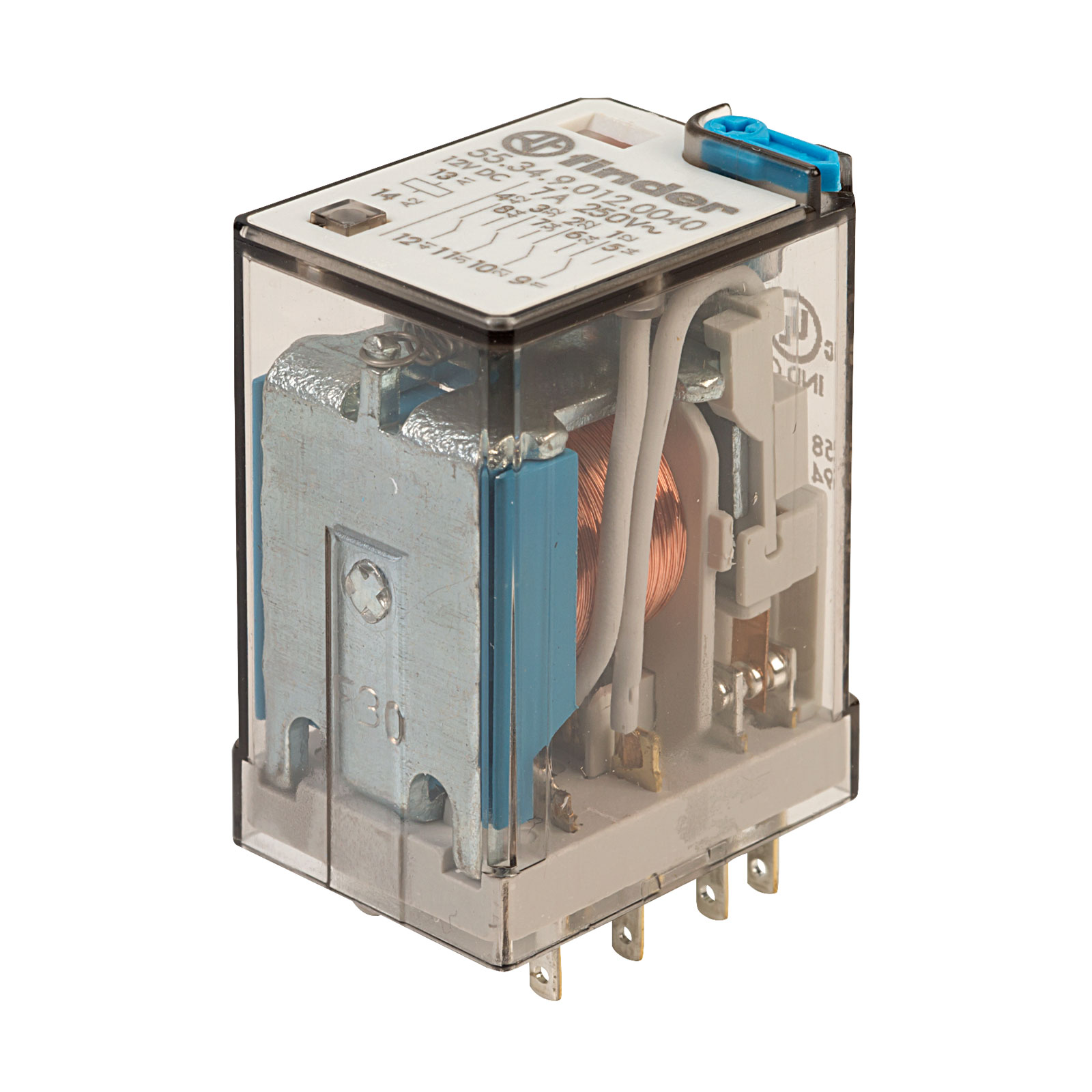

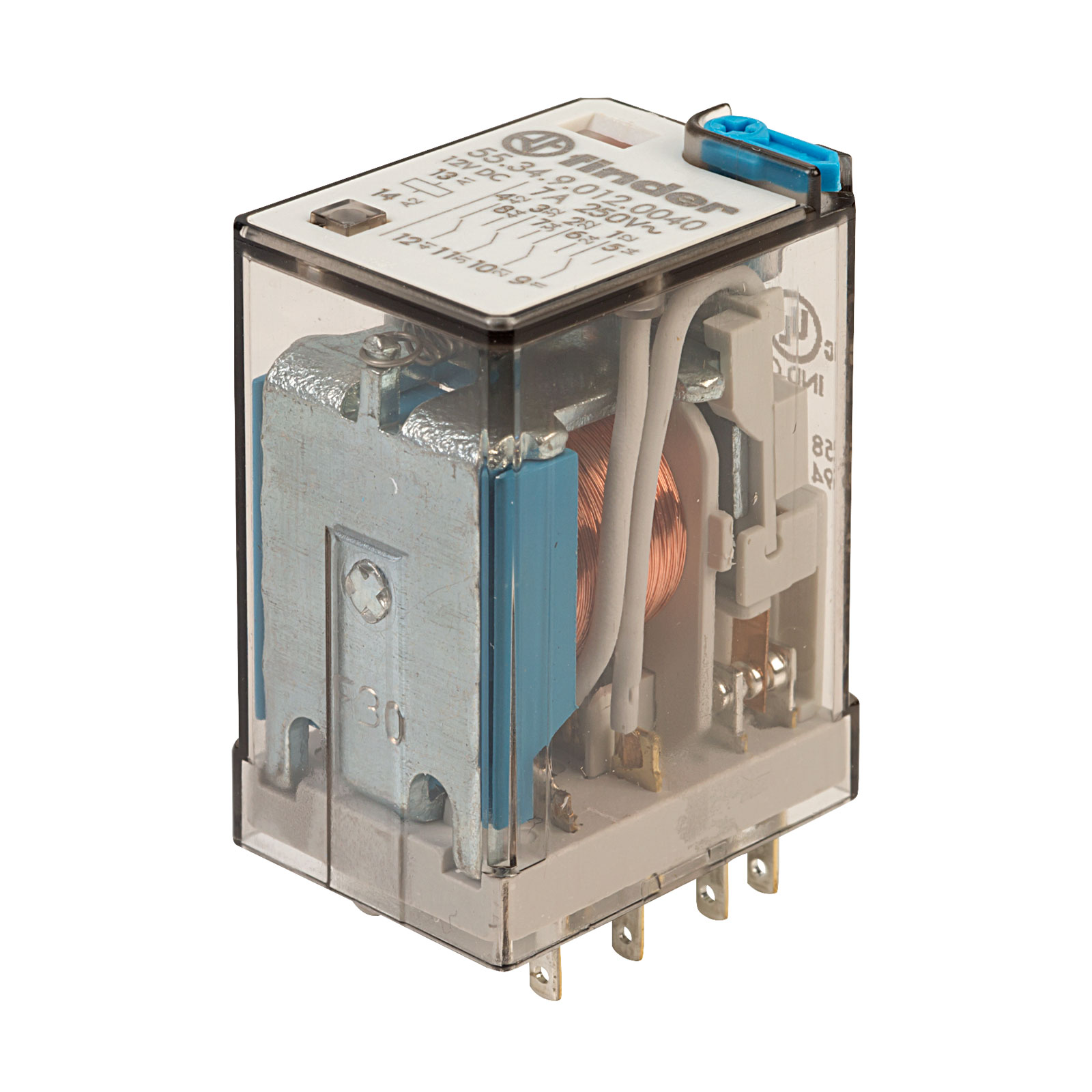

Plug-in Relays

Offer modularity and ease of replacement, suitable for control cabinets and automation systems where maintenance speed is crucial.

|

|

Solid State Relays (SSRs)

Provide silent, fast switching with no moving parts, perfect for high-speed and high-frequency applications such as semiconductor manufacturing or precision heating control.

|

|

Relay Modules

Integrate multiple relays into a single unit, simplifying wiring and installation in complex control systems.

|

Advantages of Relays in Electronics Manufacturing

Reliability and Safety

The integration of relays offers significant advantages for modern electronics, particularly within manufacturing. A primary benefit is the provision of complete electrical isolation between the control circuit and the load circuit. This is a fundamental safety measure that protects sensitive components from electrical interference and safeguards operators from high-voltage hazards. Relays can also be configured to provide circuit protection. In power distribution systems, overcurrent relays are designed to detect abnormal conditions like overloads or short circuits and automatically disconnect the circuit to prevent equipment damage or the spread of fire. A single relay with multiple, isolated contacts can be used to control multiple circuits, including those with different voltage types, which provides exceptional versatility and simplifies complex system designs.

Cost-Effectiveness and Longevity

While there are many types of relays, electromechanical relays (EMRs) are a highly cost-effective solution for many applications. They are significantly cheaper than their digital counterparts and are ideal for simple circuits where budget constraints are a primary concern. The economic value of a relay, however, extends far beyond its initial purchase price. Relays, particularly EMRs, boast a long history of proven reliability and can last for millions of cycles with minimal maintenance. For a production manager, downtime is a critical metric that directly impacts profitability. A relay that is easy to install and replace, such as the plug-in "ice cube" or "octal" relays common in industrial settings, means that a failed component can be swapped out in minutes rather than hours. This modularity and ease of maintenance drastically reduces long-term operational costs and minimizes production downtime, making a seemingly simple component a strategic choice for a system’s overall effectiveness and longevity.

Applications of Relays

The application of relays in Automated Test Equipment (ATE) provides a powerful example of their indispensable role in the most demanding electronics manufacturing processes. ATE systems are mission-critical for testing semiconductor chips, printed circuit boards (PCBs), and a wide array of other electronic equipment. These systems are incredibly complex and expensive to operate, making reliability an absolute necessity. ATE systems rely on a vast number of relays, sometimes thousands of them, to route and switch multi-channel test signals to and from the Device Under Test (DUT).

The utility of relays extends far beyond the factory floor, demonstrating their core value across various sectors. The automotive industry, for example, relies heavily on relays to convert low-power signals from the vehicle's control module or a manual switch into the high-power signals needed to operate components like headlights, horns, fuel pumps, and fan motors. This functionality protects the vehicle's sensitive control systems from high current loads, ensuring both efficiency and safety.

Similarly, relays are widely used in home and commercial systems. They are found in household appliances like washing machines to control motorized parts and in HVAC systems to manage fans, compressors, and heating elements, which ensures precise temperature control and improved energy efficiency. In telecommunications, relays are fundamental to signal routing and switching applications. They facilitate the correct routing of data and voice transmissions between different communication channels and devices while maintaining signal integrity and preventing signal degradation.

Relays & system protection

In addition to switching, relays often work in tandem with circuit breakers to enhance system protection.

While circuit breakers interrupt fault currents, relays detect abnormal conditions and trigger protective responses,

ensuring equipment safety and operational continuity.

Why relays matter in electronics manufacturing

Relays contribute to system reliability, scalability, and safety. Their ability to isolate control signals from power circuits reduces the risk of electrical interference and component damage. In automated manufacturing, relays enable precise timing and sequencing, which is vital for productivity and quality control.

Moreover, the modular nature of relay systems allows for easy upgrades and maintenance, reducing downtime and improving overall equipment effectiveness (OEE). Whether integrating relay modules into a PLC system or selecting solid state relays for noise-sensitive environments, choosing the right relay type can significantly impact performance and longevity.

Find the right relay for your business

Relays are more than just switches, they are strategic components in industrial control and automation. For electronics manufacturing professionals, understanding the nuances of control relays, power relays, and solid state relays is key to building robust and efficient systems. To explore compatible relay solutions for your next project, consider browsing related categories like circuit breakers and relay modules to ensure optimal integration and performance.

Browse full range