In today’s fast-paced industrial landscape, pick and place robotics are revolutionising how repetitive tasks are performed, boosting efficiency, precision, and scalability across manufacturing, packaging, and educational environments. These systems automate the movement of components from one location to another, reducing human error and increasing throughput. At the heart of every pick and place robot lies a sophisticated ecosystem of hardware and software, from intelligent controllers and high-torque motors to advanced sensors and human machine interfaces. Whether you're building a custom automation solution or integrating a ready-made platform like Dobot, understanding each component is key to unlocking smarter, more agile operations.

Robotic Controllers: The Brain Behind the Motion

Robotic controllers aren’t just the “brains” of a pick-and-place system, they’re the decision-makers that keep every movement precise and every process synchronised. In high-speed industrial environments, a controller’s reliability determines whether your automation runs smoothly or grinds to a halt. When latency creeps in or connectivity fails, the result can be misaligned placements, wasted materials, and costly downtime.

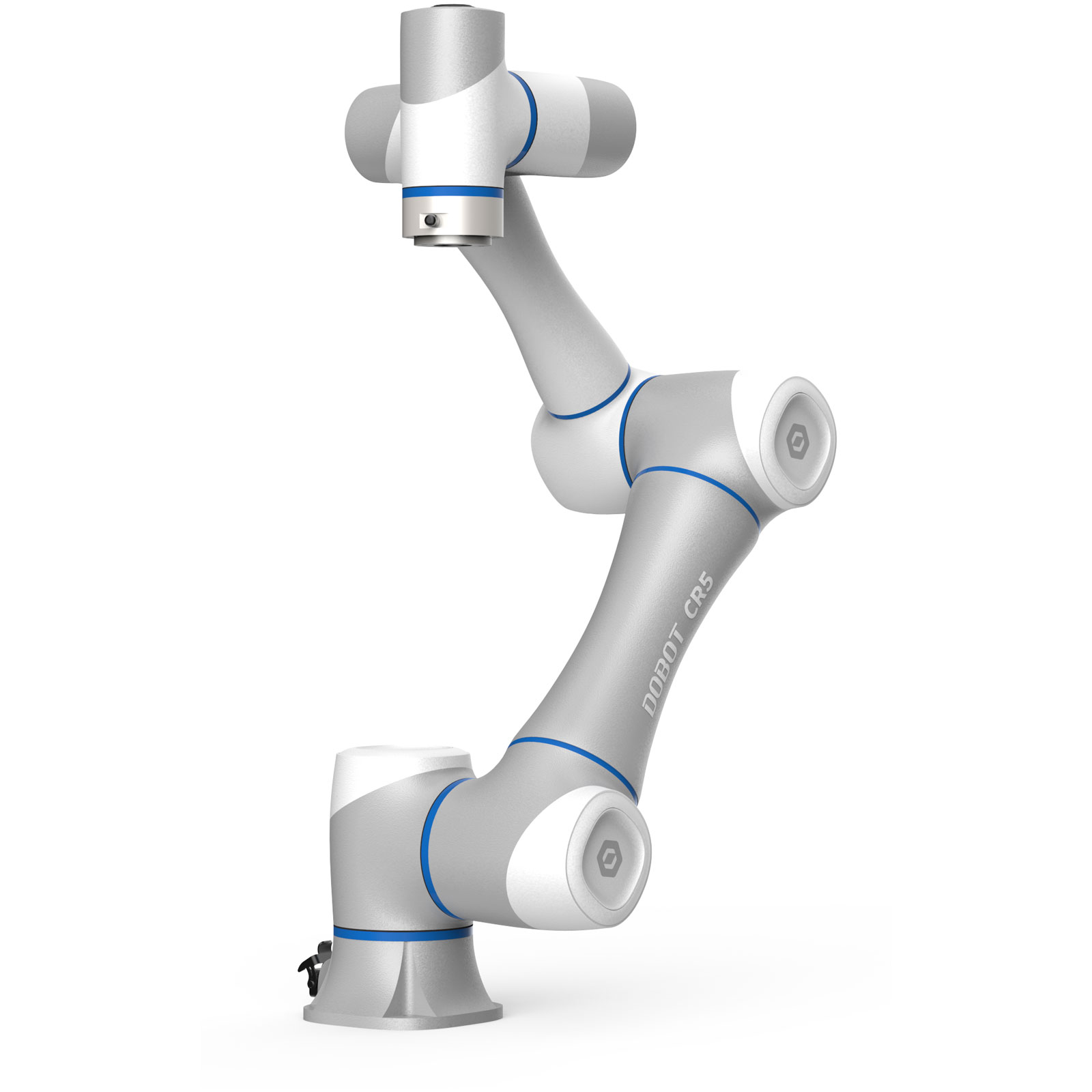

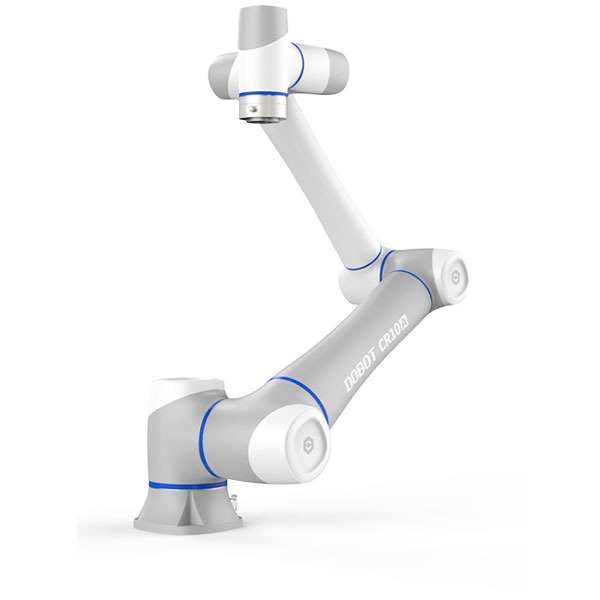

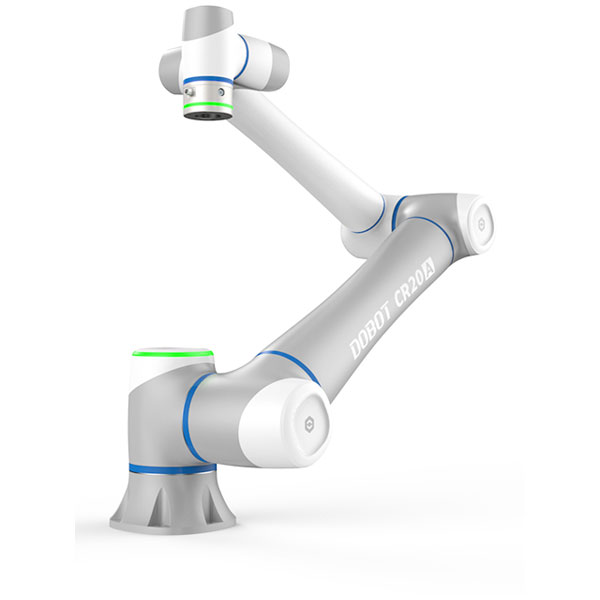

That’s why cobots like the Dobot CR Series (CR5, CR10, CR20A) are engineered for flexibility and resilience. Cobots are engineered to safely work alongside human operators in a shared workspace, typically without the need for traditional safety caging. Their defining feature is integrated safety sensors, which enable Power and Force Limiting (PFL) to detect unexpected contact and instantly halt or reduce motion to prevent injury. Cobots are known for being user-friendly, allowing non-expert staff to program them through intuitive methods like hand-guiding. They are best suited for tasks requiring flexibility and precision, such as lightweight assembly and packaging.

These robotic controllers support multiple communication protocols, USB, Ethernet, Bluetooth, so they can integrate seamlessly into diverse setups. Programming options range from intuitive drag-and-drop interfaces to advanced scripting in Python, giving engineers the freedom to prototype quickly and scale confidently.

In short, the controller isn’t just hardware - it’s the foundation of operational stability.

Actuators & Motors: Driving Mechanical Motion

Every pick-and-place robot depends on actuators and motors to convert electrical energy into precise mechanical motion. But in industrial settings, these components face relentless demands: continuous cycles, variable loads, and the need for pinpoint accuracy. A poorly chosen motor can lead to jerky movements, misaligned placements, and accelerated wear.

Servo motors stand out for their closed-loop feedback systems, delivering millimetre-level precision even under fluctuating conditions. For added safety and efficiency, Siemens motor starters protect against overloads and ensure smooth power delivery, critical for maintaining uptime in high-volume production lines.

Whether you’re assembling electronics or packaging fragile goods, selecting the right torque and speed balance isn’t just a technical detail, it’s the difference between consistent output and costly rework.

HMIs: The Human-Robot Connection

Human-Machine Interfaces are more than screens, they’re the control hub where operators interact with automation. In environments where seconds matter, an intuitive HMI can prevent errors, speed up troubleshooting, and keep production flowing. Poor interface design, on the other hand, can lead to misconfigurations and downtime.

Brands like IDEC and Siemens set the benchmark for industrial HMIs. IDEC’s FT2J series combines PLC and HMI functionality in one compact unit, reducing footprint while boosting capability. Siemens HMIs are trusted for their rugged build and advanced connectivity, ensuring they perform reliably even in harsh conditions.

Features like multi-touch gestures, glove-friendly screens, and real-time diagnostics aren’t just conveniences, they’re safeguards against operational delays and costly mistakes.

Sensors & Feedback Systems

Sensors give robots their awareness, enabling them to adapt to changing conditions. In pick-and-place systems, even a slight misread can cause cascading errors, misaligned components, jammed conveyors, or damaged products. That’s why sensor reliability is non-negotiable.

Industrial-grade options from APEM, Eaton, and Panasonic deliver consistent performance under vibration, temperature swings and electrical noise. From proximity detection to color recognition and orientation tracking, these sensors provide the feedback loops that keep automation accurate and efficient.

Think of sensors as the robot’s senses, without them, precision becomes guesswork.

Communication & Power Infrastructure

Behind every smooth-running robot is a communication and power backbone that can withstand industrial realities: heat, dust, and constant electrical load. A weak link here doesn’t just slow data, it can halt production entirely.

Industrial Ethernet Switches (IES) are ruggedized networking devices crucial for facilitating reliable, deterministic data flow among robots, PLCs, and drives in factory automation cells. Industrial Ethernet switches from Brainboxes are built for resilience, maintaining stable connections even in high-temperature environments. Wireless components like antennas from Siretta and connectors from Molex ensure robust data flow for IoT-enabled systems, where real-time feedback is critical.

Power infrastructure matters just as much. Li-ion battery packs, regulated supplies, and distribution boards keep energy delivery consistent, preventing voltage drops that could compromise motion accuracy. In automation, power isn’t just supply - it’s stability.

Mechanical Framework & Software Control

The mechanical framework is the skeleton of your robot, and its integrity determines how well the system withstands stress and vibration. Precision-engineered brackets, gears, and linkages ensure durability, while modular designs allow for easy upgrades as technology evolves.

On the software side, platforms like IDEC’s automation suite and Dobot Studio bring intelligence to the hardware. Support for Python and visual programming languages means engineers can integrate sensor feedback, motion logic, and safety protocols without reinventing the wheel.

In short, the framework and software aren’t just components - they’re the architecture of reliability.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)